T1 Mobile Wall System

Designcase T1 Mobile Display, Gallery and Museum Wall System

T1 is a new product, designed and developed by Designcase, to complement our existing range of Gallery and Museum Products, including its much larger brother - Designcase - T2 Gallery Wall System

After a prototype development phase, we are now running bulk extrusion and supplying the T1 product to market.

The T1 Mobile Wall System has been developed in our Canberra workshop, and is the culmination of our combined experience with existing proprietary wall systems, and as a response to numerous requests to develop a mobile, easy to deploy, structurally robust, modular Wall System that can be project specific manufactured in Australia.

T1 product features:

- Heavy duty internal aluminium frame structure

- Standard (or straight) Modules are based on a 1200mmW x 600mmD x 1800mmHigh Blade

- Face Panels can be made from a variety of materials, but are supplied as standard in 16mm E0MDF

- The Face Panel is intended to be a disposable commodity, replaced as or when required

- Face Panels do not need to be returned to Designcase for re-facing or patching

- A suite of wall structures will have identical components and therefore interchangeable

- Standard Wall Modules can be linked together by removing 1 of the face panels

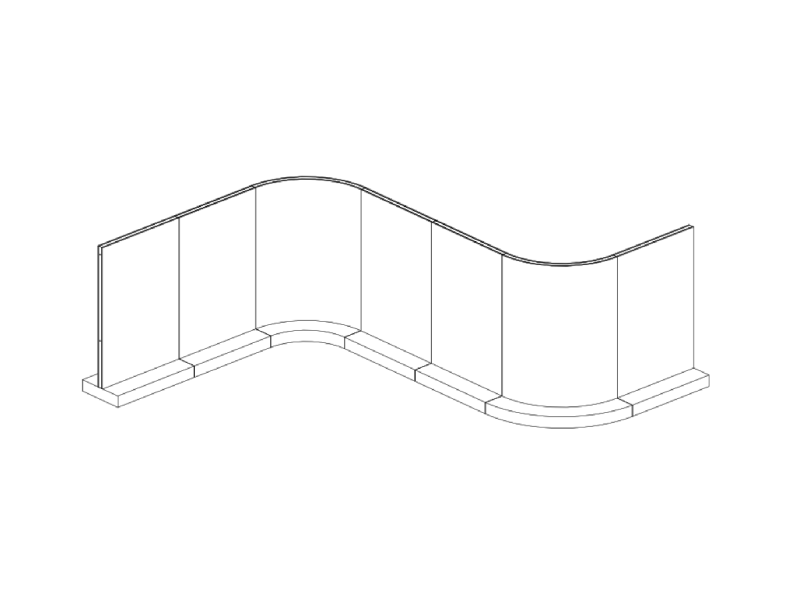

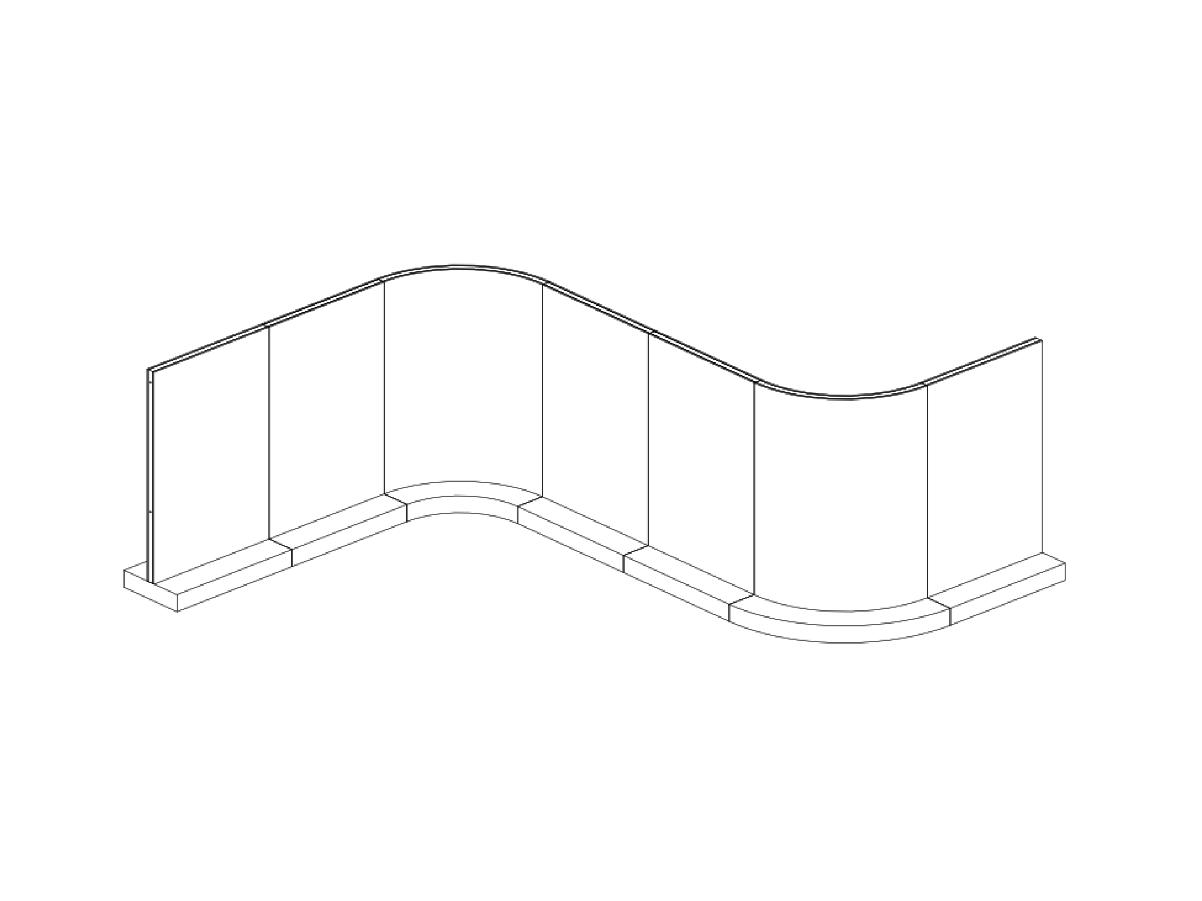

- Wall Modules are freestanding and can be mechanically fixed to a series of ‘Junctions’ to make shaped configurations: L, T, H, Z, etc.

- Assembly and demount of the Wall Modules is a simple process requiring basic hand tools only

- The standard supply of Face Panels includes a small expressed V-groove between panels

- Our T1 wall system is 100% fabricated in Canberra, ACT Australia, using Designcase's exclusive profiles and extrusion. We offer the facility to supply a range of project specific additions such as mounting Armatures, Object Plinths, etc. or replacement parts (such as face panels), and a high level of customisation as a project demands

Face Panel options can be tailored to a specific project. Our Standard Module is supplied with 16mm E0MDF, acrylic undercoat painted face panels on both sides. E0MDF is easy to patch (screw/fixing holes) and can be easily re-painted between exhibitions. Alternative face panels and face panel finishes include, but are not limited to:

- Top-coat roller-applied acrylic paint

- Graphic wrapped / graphic applied

- Art Hanging Tracks / Art mounting

- Pin Board face panels

- Acoustic face panels

- Front-of-House / Back-of-House

- Slat-Wall and Retail

Linking Sections / Corner Junctions and In-fill Blades. Linking T1 walls end-to-end is a simple and easy process; building long straight runs of display wall. The use of simple in-fill sections, 90-degree corner sections, L or X shape linking sections allows more complex foot-print configurations to be made, such as T, L and U-shape spaces and ‘rooms’. See following illustrations. We also offer a non-standard linking section service which can be made to any angle, or curved sections, rather than a standard 90-degree return.

If you have any queries regarding the Designcase T1 and T2 Gallery Walls, or any of our Proprietary Showcases, or our Museum lighting options from LjusDesign, please do not hesitate to contact me.